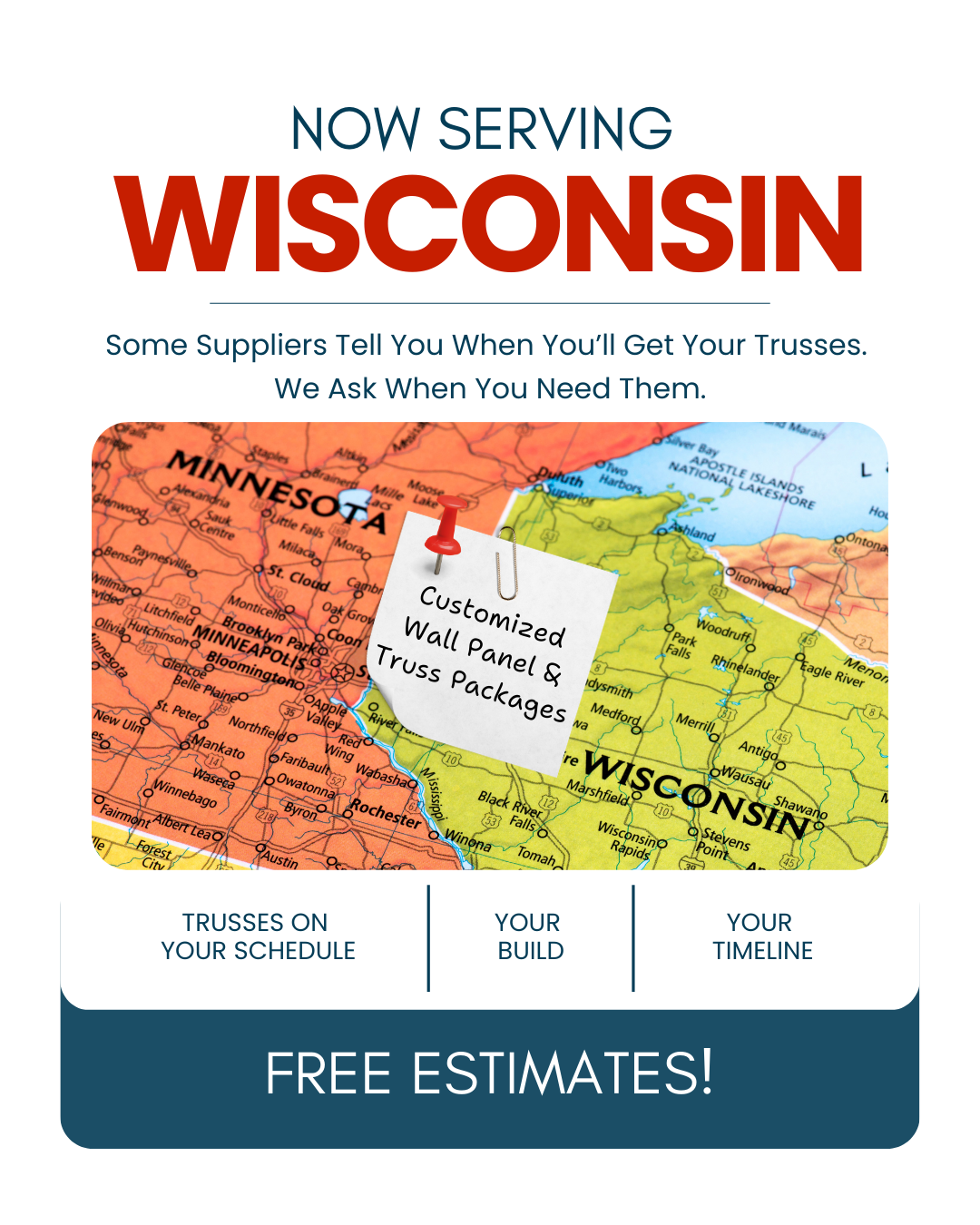

Wisconsin Truss manufacturing at scale

High-quality roof and floor truss packages engineered, manufactured, and delivered for Wisconsin builders who need reliability, speed, and precision.

Built for Wisconsin Builders

Wisconsin projects demand durability, consistency, and a partner who understands regional construction methods, climate considerations, and scheduling realities. Our truss packages are designed to support a wide range of Wisconsin builds—from multifamily and townhomes to custom single-family homes and light commercial projects.

We combine advanced truss design software, state-of-the-art manufacturing equipment, and experienced production teams to deliver trusses that install cleanly and perform long-term.

State-of-the-art truss manufacturing facility

Our truss manufacturing facility—built within the last five years—was designed specifically for high-volume, high-precision production. Advanced automation, tight quality control, and optimized workflows allow us to maintain speed without sacrificing accuracy.

Roof and floor trusses for residential and multifamily projects

Complex truss designs including long spans and custom geometries

Consistent quality through controlled indoor manufacturing

Capacity to scale as project demand increases

Proven across project types

Our Wisconsin truss packages support a wide range of construction types:

single-family homes

apartments & Mixed use

townhomes & multifamily

Commercial & post-frame

see how minnesota’s truss packages are built

From raw lumber to jobsite-ready trusses - take a look inside how we manufacture truss packages trusted across Minnesota.

Frequently Asked Questions

-

We work with standard file formats including Mitek Sapphire, CAD (.dwg), Revit (.rvt), and PDF. Early coordination helps us optimize prefabrication and avoid costly field changes.

-

Yes. Our team partners with architects and engineers to recommend efficient framing layouts, material alternatives, and prefabricated solutions that reduce cost without compromising structural integrity.

-

The earlier, the better. Involving us during schematic or design development allows our team to align with your plans, provide engineering input, and coordinate prefabrication details that streamline construction.

-

Yes. All trusses are designed and engineered to meet or exceed Minnesota building codes and regional requirements.

-

Absolutely. We provide engineered and stamped drawings for trusses as required for permitting and inspections.

-

Prefabricated trusses reduce on-site labor needs, speed up installation, and minimize weather-related delays. Many builders report weeks shaved off their framing schedule.

-

JL Schwieters is one of the only Minnesota framing companies that uses safety poles on every project to keep crews protected. Our OSHA-trained teams follow strict safety protocols, while continuous quality checks in both manufacturing and installation ensure precision and reliability on every job.

-

Yes. Builders and contractors can purchase wall panel packages, truss packages, or complete material packages for self-installation.

-

Lead times vary by season and project size. Contact our sales team for current availability.

Featured truss package Projects

amira of lake elmo

post frame project

Richfield, MN